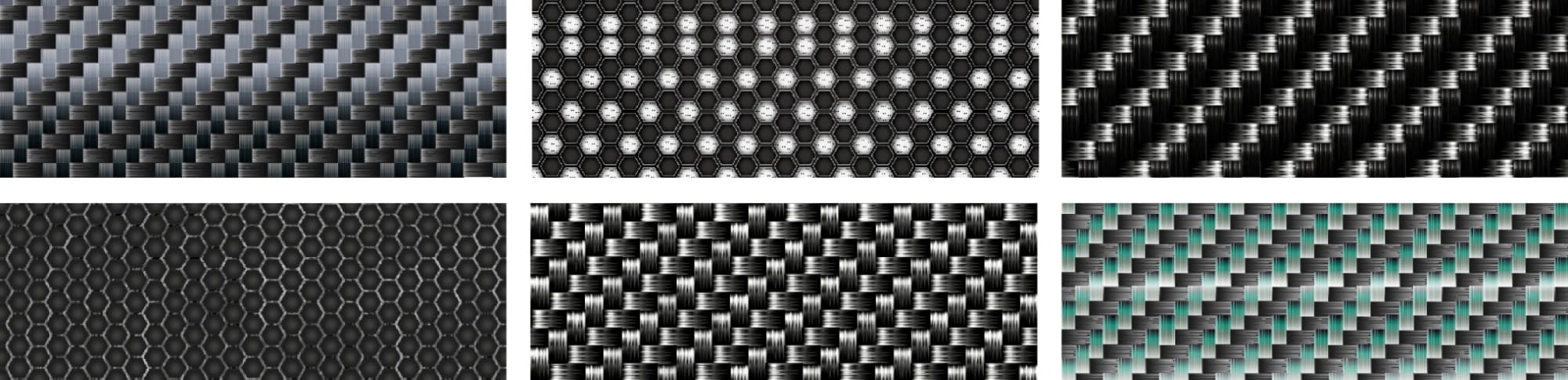

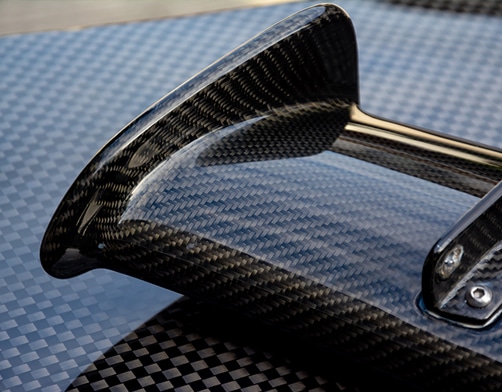

The growing popularity of using composite materials in a lightweight construction has become a megatrend. This is true not just in the automotive industry but also in the aerospace and construction sectors. Composite materials such as carbon and glass fibre reinforced polymers can significantly reduce the weight of the structural components and cut energy consumption and CO2 emissions. The lightweight and flexible features of the composites has made it one of the most promising alternatives for conventional metallic structure.

ETG has many years of experience in developing new technologies for lightweight construction using composite materials. With close collaboration with leading academic and industry partners across the UK and Europe, we combine advanced technology with industrial know-how to create unique and innovative solutions to suit your needs.

From bespoke composite moulding tools, end effectors to multi-material handling and joining, you can rely on our experience to deliver high-quality components and cost-effective manufacturing processes. No matter what your demands are, we are always pleased to have a discussion!